Products

Overmoulded Cable Assembly

Button

Slide title

Box Build Fully Assembled and Tested

Button

Medical Cable Assembly

Button

Slide title

Complex Multi Point Cable Assembly

Button

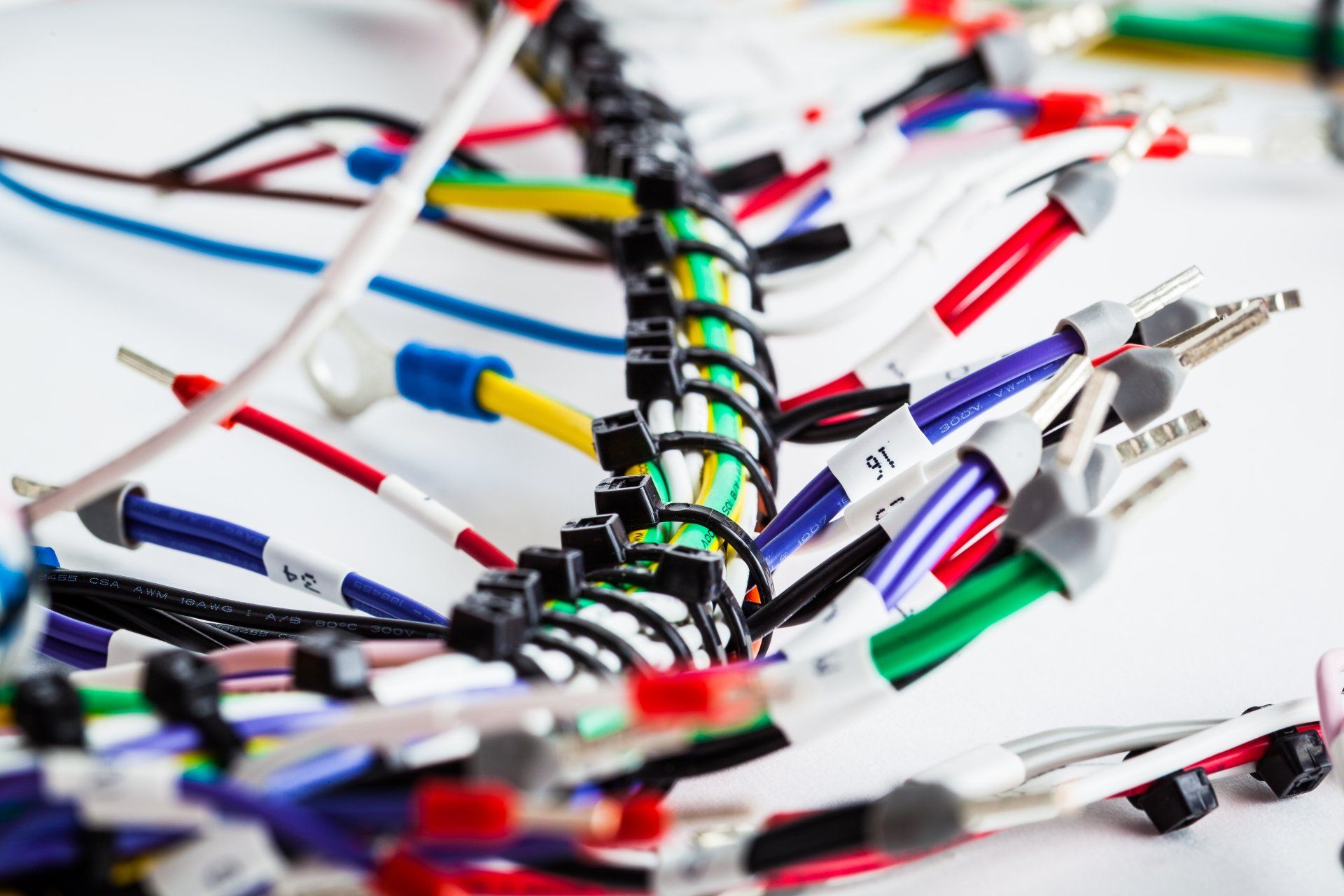

Cable Assembly, Loom and Box Build

The type and number of cable assemblies we supply is vast and constantly growing! From a simple cut and strip wire to a 50 metre length multi-point loom with over 100 connectors, we can supply all of our customers' requirements. Key capabilities include:

Crimping from 40AWG+

All wire sizes and types capable of full assembly

All Manufacturers Supported

Tyco, JST, Molex, Hirose, JAE, Deutsch, Souriau, Lemo, Fischer and FCI and others!

Overmoulding / Double Moulds

High & Low temperature materials: PVC, PU, Silicone etc

Stake Welding / Laser Welding

For robust plastic assembly

Cable Marking

Laser, Heat Shrink - fully customised identification

Waterproof and IP65 Solutions

For preventing water, dust, or salt spray ingress

100% Fully Tested as Standard

100% electrical test for continuity, shorts, crossed wires

Custom Testing Available

Flash, Hi-Pot, Impedance and customised testing

High Mix / Low Volume

Fully supported with our local logistics

Product Highlights

Box Build

Fully built and finished parts - all wiring, components and metalwork supplied by us (see photo for example)

Ribbon / IDC Cables

Flat and round cable types supported

Coaxial / Semi Rigid Cables

All connector types supported

Power Cords

Customised and Standard Assemblies

Network and Data Cables

Including the latest technologies such as USB 3.0, Cat 7

Computer and Video Cables

LVDS, SCSI, Displayport among many others

Audio Video (AV) Cables

Including custom electronic assemblies

Medical Cable Assemblies

Quality controlled with ISO13485 and UL approvals

Slide title

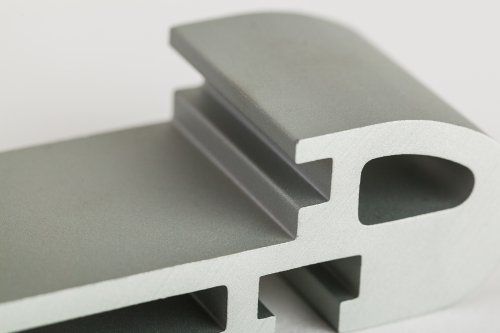

Extrusion with Anodised Finish

Button

Slide title

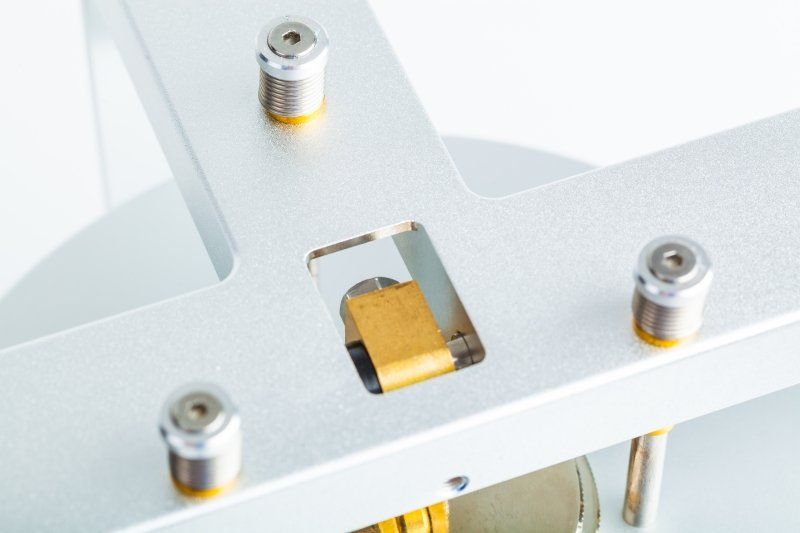

Machined Parts to High Tolerances

Button

Slide title

High Quality Cosmetic Finishes

Button

Slide title

Complex Metal Assemblies

Button

Metal Precision Components and Assemblies

Cableplus Europe are a leading supplier of metal precision components and customised assemblies. Investment in the latest machinery means we can deliver the highest quality parts to you at the right cost. Key capabilities include:

5 Axis CNC

Machining to the highest tolerances

Casting

Die Casting, Vacuum, Sand, Investment Cast

Turning

Chamfering, parting, threading, boring, drilling, knurling

Forging

Reduces waste and therefore unit cost

Extrusion

Finished and machined to your requirements

Stamping

Progressive, Transfer, Stage, Deep Drawing

EDM Wire Cutting

Ideal for prototyping or low volumes

Laser Cutting

No tooling costs also highly accurate

Cosmetic Finishing

We have great experience in finishing metal parts and assemblies to the highest cosmetic standard. This is well suited to demanding end markets such as medical (life critical, high temp), industrial (UV, salt spray, humidity, high temp), automotive and the renewable sector. We offer the following finishes:

Pre-Treatment

Sand blast, brush, polish, heat treatment, grind

Cleaning

Medical microbial cleaning

Anodising

Tolerance to several microns, clear or coloured

Plating

Electroless Nickel Plating, Chrome, Silver

Passivation

Zinc, Stainless Steel

Powder Coating / E-Coating

Die Casting, Vacuum, Sand, Investment Cast

Plastic Injection Moulding, Parts and Assemblies

We have extensive knowledge of manufacturing plastic parts and assemblies to high tolerances. This know-how of process flow and product history enables us to deliver the best quality solution for your individual project requirements. Our injection moulding machinery ranges from 40 to 1,300 tonnes so we can offer products from the smallest micro-connector up to a large medical base housing.

Injection Mould Tooling

Design and feasibility

Finishing

Powder Coating, Spraying, Printing, Parylene

Vacuum Forming

Design and feasibility

Extrusion

PVC (flexible, rigid, nitrile), TPR, HIPS, PP, LDPE, MDPE, HDPE

Turning

Using our cutting edge technology CNC machinery

Blow Moulding

Hollow parts in HDPE, LDPE, PP, TPE, Nylon, ABS, K resin

Slide title

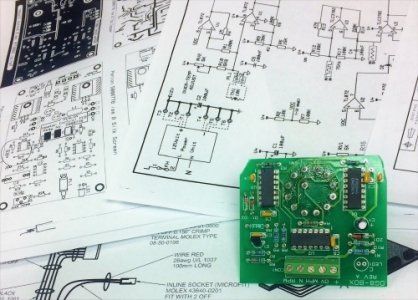

SMT / Radial / Axial Assembly

100% Tested

Button

Slide title

Potting and Overmoulding

Conformal and Parylene Coating

Button

PCB and PCBA

We are a world class source for PCB and PCBA with an established track record of high quality supply. As with all our other product ranges, we can assist you with design and prototype stages prior to manufacture. Our comprehensive supply chain allows us to integrate a PCB with our other technologies such as moulding and cable assembly. This creates a simple, one stop resource for your requirements.

Surface Mount Technology

SMT

Radial and Axial Assembly

Including Pin Through Hole

Manual Assembly

With 100% testing

Potting and Overmoulding

For IP rated encapsulation

Coating

Paralene, Conformal, Custom

Testing Methods

BGA, X-Ray, In-Circuit Testing, Functional Test

Custom Components with OEM Design

The range of parts that are identified in this product category is extremely diverse and constantly growing due to strong customer demand. Our expertise in world class supplier identification and quality control has allowed us to add to our product portfolio of custom components.

Cartridge Heaters

- Heat transfer component

- Temperatures up to 800°C

- Simple push fit into pre-drilled holes

- Custom termination and lengths

PTFE, FEP and Rubber Seals

- PTFE seals withstand high temperatures (–70 to +250°C) and aggressive end applications

- High tolerances for critical sealing dimensions

- Also in: NBR, Neoprene, EPDM, Silicone, Viton, PU

- Custom shapes and OEM design available

Membrane Switches

- Available as: Tactile, Non Tactile, Shielding, Back Lighting, Embedded LED and Resistor

- Activation strengths from 8mm to 20mm

- IP Rated and UV Resistance available

- Custom shapes and any connectivity option

Silicone Keypad

- Typical activation force: 100-300g and travel between 0.8-2mm

- High temperature, chemical resistant to FDA, flame retardant options

- Translucent and Luminescent options available

- Custom shapes and bespoke design offered

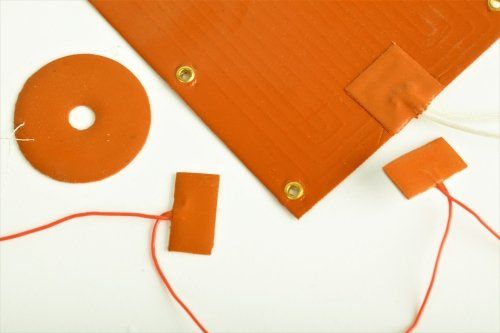

Silicone Heater Pads

- Wire-wound or etched foil heating elements

- Operating temperatures range from -60°C to 250°C

- Good chemical resistance

- Custom shapes and sizes, up to 10 metres²

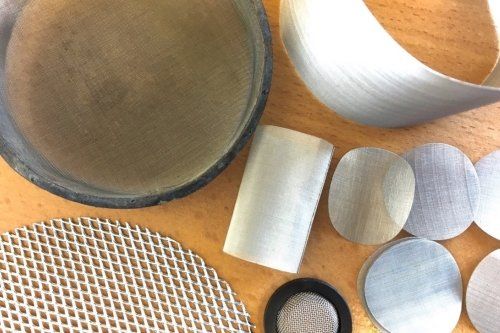

Wire Mesh and Filter Washer

- Wire mesh available from 0.025mm hole size upwards

- Filters suitable for industrial, automotive, electronics and domestic applications

- Over moulded mesh parts in PVC, Rubber and other materials

- Custom forms and assemblies offered

Slide title

Knobs with Anodised Finish

Button

Slide title

Drawer Slide

Button

Slide title

Dual Wall Carton with Foam Inserts

Button

Standard Components

Driven by customer demand, Cableplus Europe have expanded their product offering to include standard components. Usually these are available as standard items (ex-stock or on short lead times) or they can be customised according to your requirements.