Why Choose Us?

Why Choose Us? - 3 Simple Reasons

Reduce Cost

With fixed price contracts and no hidden or extra delivery charges to you.

Finished stock at our UK facilities improves your cash flow and reduces your storage overheads.

Reduce Risk

We manage all aspects of the supply chain via our local quality team. By regularly auditing our factories we ensure product compliance and best service is offered at all times.

Also we reduce your lead time and liabilities by stocking parts in our UK facilities.

Reduce Complexity

Being a single point of contact allows you to focus on running your business.

All logistics, handling and importation is arranged by our local team and we deliver direct to your door.

Slide title

Write your caption hereButton

Quality Control

Supply Chain Audits

Bi-annual supplier visits are made by our team to audit facilities and address any ongoing issues.

We have a simple philosophy which has stood us in good stead - We do not trade with companies who have not been audited or personally visited by our team.

Product Development and Supplier Selection

Our experience means we choose the right partner in our supply chain to deliver world class quality to you. ISIR, PSW or PPAP documentation are all available with sample submission to ensure prototypes are approved quickly to your satisfaction.

Incoming Quality Inspection - Dimensional, Visual, Electronic, Functional

Whilst setting up individual parts on our MRP system we can specify the incoming inspection levels and the type of test.

So we can either look for cosmetic defects, check dimensions or perform electronic or functional tests locally to verify the quality is acceptable.

Ongoing Quality Records, Corrective Actions, Improvements to Process Flow

If we have have any quality issues our first thought is always to maintain supply chain, identify root cause and implement corrective actions as soon as possible. This is pursued in a robust and efficient manner to ensure quality compliance is restored to product supply immediately.

We also interrogate the manufacturing process flow at this stage to see if any improvements can be made before presenting our findings in a formal corrective action report (CAR), 8D or FMEA for the automotive sector.

Approvals include:

ISO9001, TS16949, ISO13485 and ISO14001

Project Management

Quotation

Drawings and samples are carefully reviewed to ensure the right materials and suppliers are selected. This in turn will deliver the best quality solution for you at a competitive price point.

Engineering, Prototyping and Product Development

Sample inspection reports control critical dimensions, cosmetic appearance and functional attributes of your products.

Pre-Production and Production

Orders are expedited by our local team so we can keep you informed with the latest delivery dates.

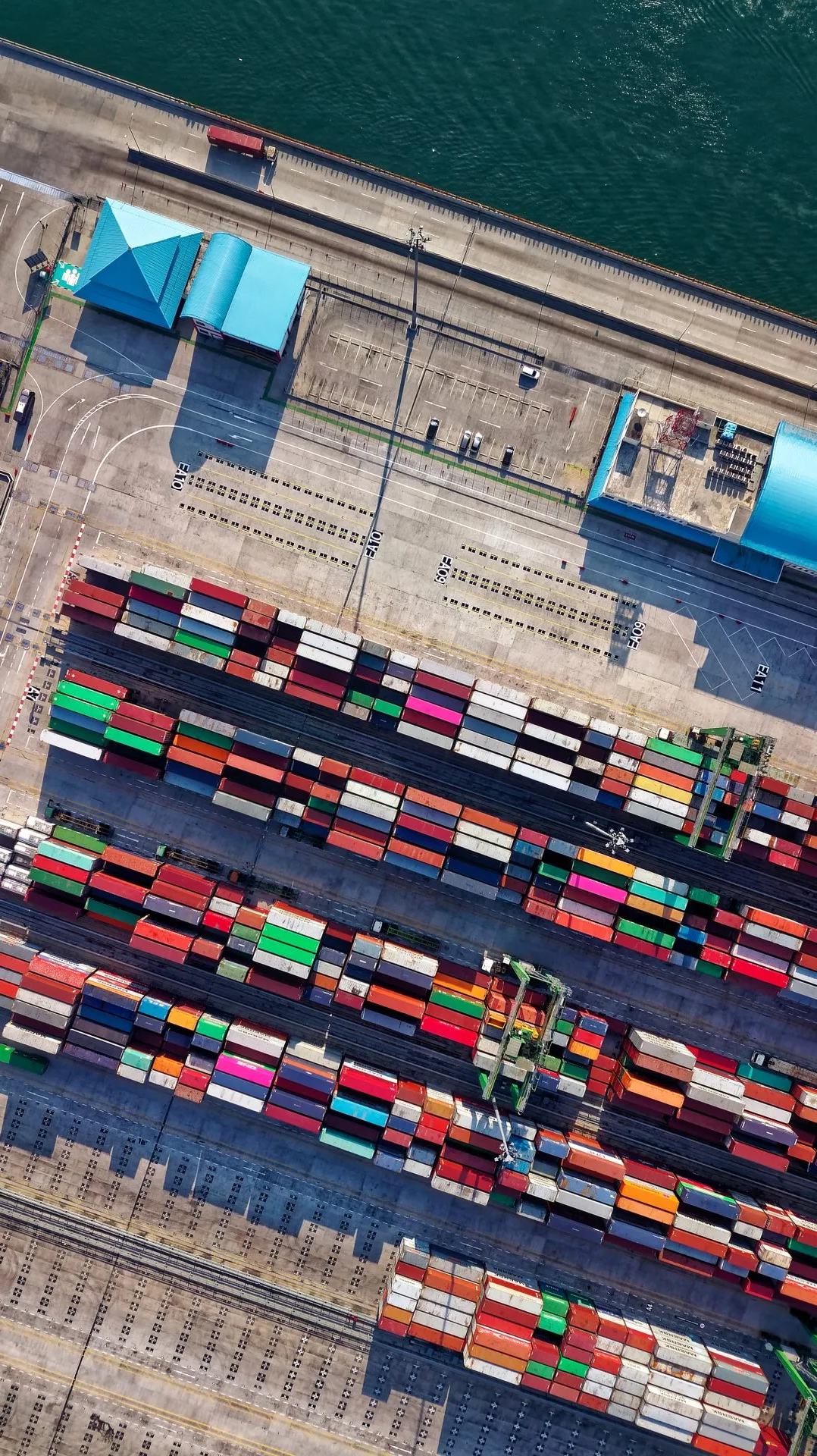

Logistics

We organise the door to door shipment and all customs and regulatory clearance is taken care of on your behalf.

Inventory and Quality Management

Parts are subject to strict incoming quality controls. After approval they are stocked according to your order requirements.

Ongoing Service

Order progression and detailed information is provided to customers at each stage of the process. We keep you updated with details and the progress of your parts.

New Product Development

Reverse Engineering

From golden samples of products, we are able to then reverse engineer the parts and start samples extremely quickly.

Rapid Prototyping

For plastic parts, we often use 3D printing and for metal parts we use CNC or laser cutting to shorten your time to market.

Cost Analysis Engineering

Working closely with our approved suppliers means we can help you deliver both a high quality product and an acceptable price.

Pre-Production and Tool Validation

During this critical stage of product development we closely monitor part and tool performance.

Quality Engineering

We can help you re-engineer problematic components or assemblies and improve the acceptable quality level (AQL).

Managed Logistics

Order Progression

Our local team will keep you posted as to the latest progress of your orders and your current stock levels.

Once parts are landed in the UK you have the flexibility to call off according to your demands.

Door to Door Service

The entire shipping process is controlled from factory to your door. We organise the best means of transport, either by Ocean or Air and take care of all import requirements for you.

All stock is fully insured in transit and will be packaged to ensure your parts arrive undamaged.

Managed Quality

Goods received are controlled using incoming inspection (IQC) which can be customised according to each individual part.

Full traceability is ensured using our MRP system which maintains order history information.

Just in Time Delivery

Cableplus Europe is accustomed to dealing with the individual customer requirements of Kanban, MRP, and CRP systems.

When your deliveries are time critical we can use our own transport to deliver within your deadline.